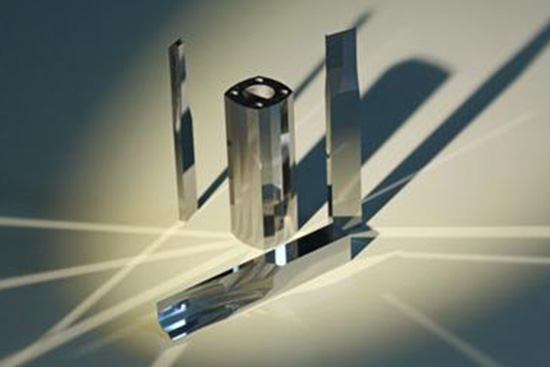

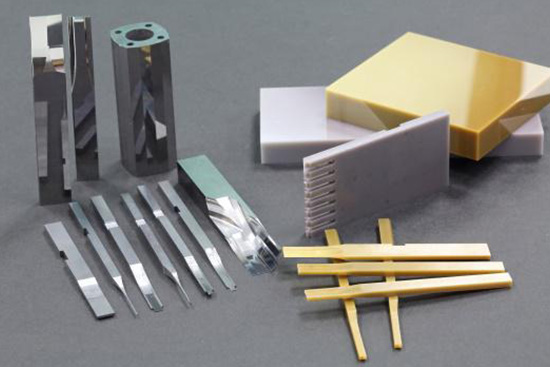

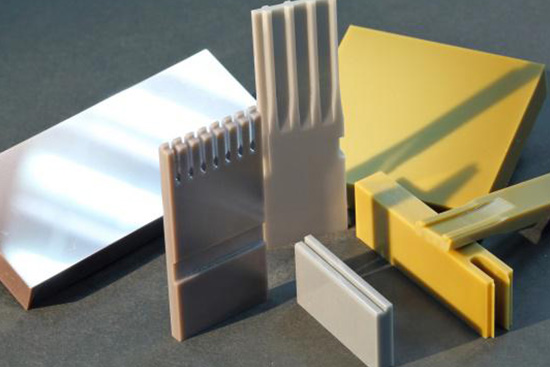

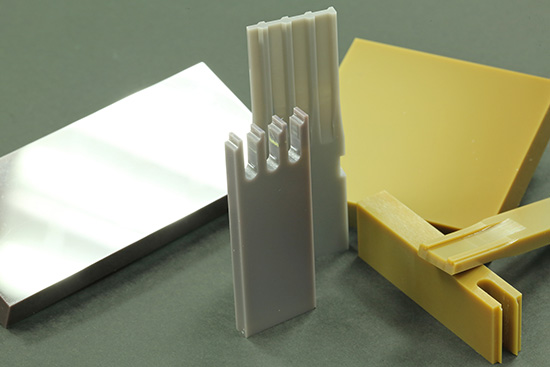

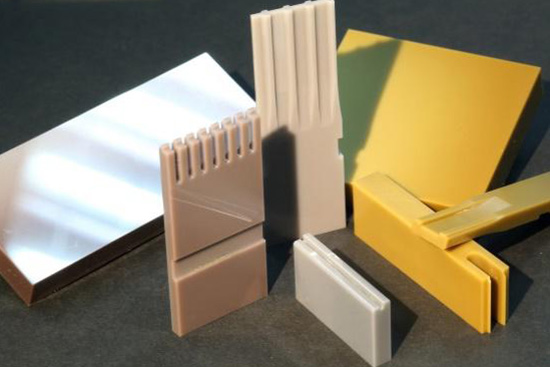

Ceramics ( Z-KAC-901 ) and ( CRZ-3 )

- With excellent corrosion resistance, binding agent is hard to be corroded and decomposed.

- Molds can avoid sticking and scratching materials

- Lightweighted, its density is less than half of the tungsten carbide.

- Morocrystal and homogenerous micro tissue structure.

- Full compact and imporous materials.

- Extremely low coefficient of friction.

- Applicable to precise metal forming molds, bending molds, stamping molds, and high anti-abrasive parts.

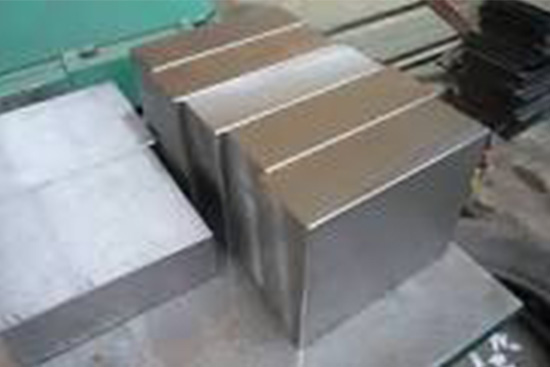

Steel ( HIS-9, SKD-11 and T15 )

Carbide’s tissue is tiny orderly, and well distributed, so its abrasive resistance toughness are better. Especially it is increased and descreased by its content, so its high temperature characteristic will not be damaged and the steel quality can be continously and significantly improved. The hot working and cold working are possible, and machinability and abrasiveness are good.

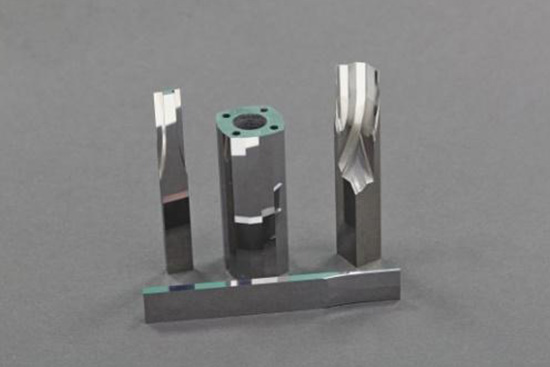

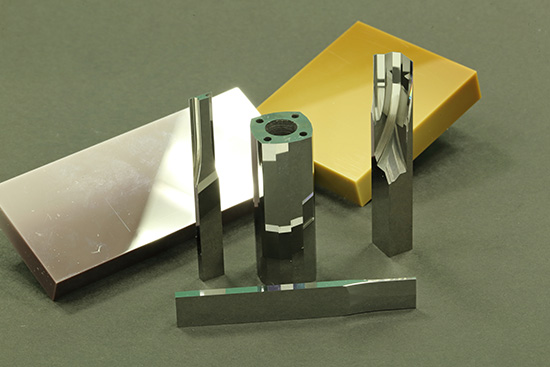

Tungsten steel

Tungsten steel (hard alloy) is high in hardness, and good in abrasive resistance and toughness, heat resistant and corrosion resistant, and is widely used in tools like lathe tool, milling tool, planing tool, drill, boring tool, etc for cutting cast irons, nonferrous metals, plastics, chemical fibers, graphites, glass, stones, and common steels.